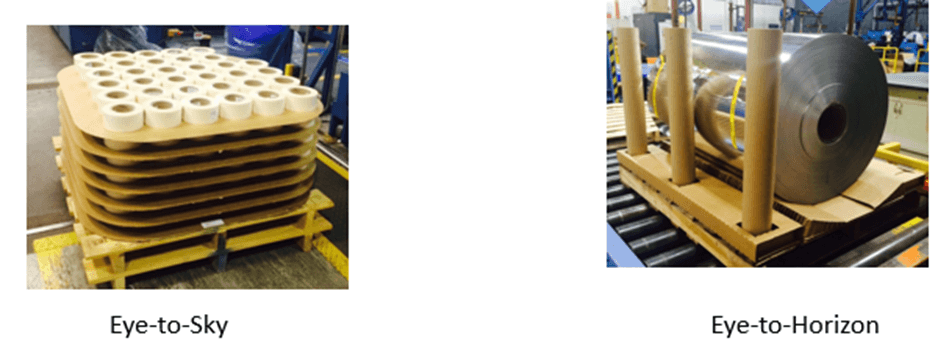

Based upon customer request, rolls can be packaged eye-to-sky or eye-to-horizon.

Yes, we treat all of our laminated foils with either a clear or opaque coating to help prevent oxidation of the aluminum.

Yes, we have one and two color capabilities.

LLFlex is certified to the standard ISO9001:2015.

Yes, send LLFlex a sample of the material you would like matched.

A foreign trade zone, FTZ, is a designated facility authorized by the Federal Government that is legally considered to be outside of the U.S. Customs and Border Protection, CBP, territory of the United States for the purpose of tariff laws and CBP entry procedures.

The FTZ helps facilitate and expedite LLFlex’s involvement in international trade, both with imports to the US and export to our customers. Other benefits include streamlined logistics, inverted tariffs, duty deferral, and duty exemption. While in the zone, merchandise is not subject to the U.S. duties, tariffs, or exercise tax. The rate of duty imposed on the merchandise admitted to the zone may change as a result of manufacturing operation conducted within the zone. This allows duty to be paid on the finished product as opposed to the imported component. Merchandise may be exported from the FTZ duty and tax free.

The FTZ allows LLFlex to be globally competitive in the industry by attracting offshore activity, encouraging domestic production of material. The FTZ removes certain disincentives associated with domestic manufacturing by balancing the tariffs placed on imported components and the finished product. The FTZ assists in state and local developmental efforts and creates many employment opportunities.

This requires three pieces of information:

Basic Equations:

To convert from Area to weight requires three pieces of information:

Basic Equations:

Imperial (English) units:

Mil = 0.001″ (one thousandth of an inch)

Metric Units:

Micron (1 mil = 25.4 Microns = 0.001”)

Referred to as Gauge for Film (100 GA = 0.001″)

Referred to as Point for Board (8 PT = 0.008″)