Building Material Solutions Developed for Array of Markets and Evolving Requirements

Building Material Solutions Developed for Array of Markets and Evolving Requirements

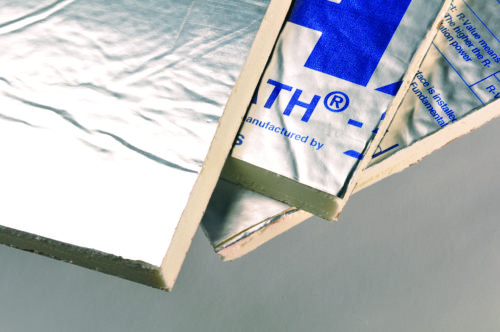

Louisville, KY – LLFlex – a global leader in packaging materials and industrial laminate solutions for the building & construction, wire & cable, and tobacco packaging industries, has developed a full line of insulation facers that address the industry’s exacting requirements for gas and moisture barrier while enhancing the superior durability and longevity of the polyiso foam insulation boards. Dubbed ReyFlex™, the product set aligns with LLFlex’s commitment to energy conservation and high performance for all building & construction markets, including commercial, industrial, residential and retrofit.

The ReyFlex™ portfolio of insulation facers is comprised of three products:

- The ReyFlex™ Tri-Laminate Insulation Facer is available in a variety of basis weights ranging from 25-50lbs, with foil applied on both sides. Utilized for rigid foam insulation, this option functions as an ultimate barrier for maintaining R-Values, while simultaneously providing superior foam adhesion. Where added puncture resistance or durability is required, ReyFlex™ Tri-Laminate “Tough” Insulation Facer can utilize a foil/paper/polyester film format to provide added durability to rigid foam insulation panels.

- A foil and paper bi-laminate faced insulation solution, the ReyFlex™ Bi-Laminate Insulation Facer was developed as a lower cost alternative to Tri-Laminate for both rigid foam and fibrous insulation mediums and is available in 25 to 50lbs basis weights.

- LLFlex’s ReyFlex™ 20LB Bi-Laminate for Radiant Barrier applications provides a low emissivity surface from the pure aluminum foil resulting in high reflectivity. Available with or without perforation for moisture permeability, the Bi-Laminate can be applied to a multitude of building substrates, including OSB and plywood.

“As industry requirements evolve, LLFlex continues to develop new solutions for our customers,” said Victor Dixon, CEO of LLFlex. “We are committed to expanding our line of innovative products to ensure our facer performance continues to exceed customers’ expectations.”

###

About LLFlex, LLC

LLFlex, LLC is a leader in packaging materials and industrial laminate solutions for the building & construction, wire & cable, and tobacco packaging & other printable substrate markets. The company has operations in Kentucky and North Carolina. LLFlex markets its product portfolio through its network of global agents and partners.

For the building & construction sectors, LLFlex provides a full line of laminated insulation and radiant barrier facers designed to meet the industry’s requirements for gas & moisture barrier, product adhesion, reflectivity, durability, and longevity. For the wire & cable industry, the company’s Reyshield™ Cable Wrap yields a line of mono and co-ex layered film formulations using proven, high quality resins throughout the structure for consistent, reliable long-term performance. For tobacco packaging, LLFlex is North America’s largest supplier of cigarette inner bundling material, as well as custom-printed laminations for cigar, pipe and smokeless tobacco.

For more information, call (800) 634-3645 or visit www.llflex.com.